CRT 無屑絲攻

以塑性加工方法做為母螺紋的加工用工具,適用於延展性良好的低炭鋼、低炭素合金鋼、不鏽鋼及非鐵金屬的攻牙作業。

Using plastic working to produce internal thread, this tap is suitable tapping for low carbon steel, alloy steel, stainless steel and nonferrous metals good stringy materials.

無屑絲攻之特長Features of fluteless taps

•攻牙時不會產生切屑,因沒有切屑適合於盲孔的螺紋加工且可以省卻切屑的處理時間。

•沒有切屑槽,絲攻斷面積較大,亦沒有切屑的干擾故不易折損。

•良好的母螺紋之有效徑精度。

•母螺紋塑性流動成形面粗度良好,有效徑之偏差較少。

•They are suitable for blind hole tapping in producing internal thread with no chips, they save you a time for disposal chip.

•The effect of fluteless gives a large cross-section area to the tap that effectively eliminates the problem of chip jamming and thus make roll very strong.

•Fluteless tap produce excellent pitch diameter well within pitch diameter tolerances.

•Material defomation process produces the internal thread with good surface finish as well as precise pitch diameter.

|

公制牙標稱規格 |

精度 |

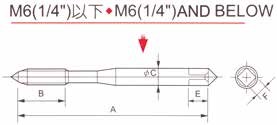

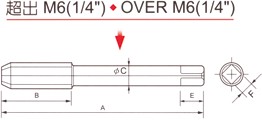

形狀尺寸 Specification |

2級下孔徑參考值 Class 2 drill hole dia |

|||||

|

A |

B |

C |

E |

F |

最小-最大 |

咬 合 率 % |

||

|

M3 x 0.5 |

R5 |

46 |

9 |

4 |

6 |

3.2 |

2.76 ~ 2.81 |

100 ~ 75 |

|

M3.5 x 0.6 |

R5 |

48 |

11 |

4 |

6 |

3.2 |

3.20 ~ 3.26 |

100 ~ 75 |

|

M4 x 0.7 |

R6 |

52 |

12 |

5 |

7 |

4 |

3.65 ~ 3.70 |

100 ~ 85 |

|

M5 x 0.8 |

R6 |

60 |

14.5 |

5.5 |

7 |

4.5 |

4.59 ~ 4.66 |

100 ~ 80 |

|

M6 x 1.0 |

R7 |

62 |

17.5 |

6 |

7 |

4.5 |

5.48 ~ 5.57 |

100 ~ 80 |

|

M7 x 1.0 |

R7 |

65 |

13 |

6.2 |

8 |

5 |

6.48 ~ 6.57 |

100 ~ 80 |

|

M8 x 1.25 |

R7 |

70 |

18 |

6.2 |

8 |

5 |

7.34 ~ 7.41 |

100 ~ 85 |

|

M10 x 1.25 |

R7 |

75 |

19 |

7 |

8 |

5.5 |

9.34 ~ 9.41 |

100 ~ 85 |

|

M10 x 1.5 |

R7 |

75 |

19 |

7 |

8 |

5.5 |

9.18 ~ 9.28 |

100 ~ 85 |

|

M12 x 1.75 |

R8 |

82 |

23 |

8.5 |

9 |

6.5 |

11.05 ~ 11.15 |

100 ~ 85 |

|

M14 x 2 |

R10 |

88 |

25 |

10.5 |

11 |

8 |

12.92 ~ 13.04 |

100 ~ 85 |

|

M16 x 2 |

R10 |

95 |

27 |

12.5 |

13 |

10 |

14.92 ~ 15.04 |

100 ~ 85 |

|

M18 x 2.5 |

R11 |

100 |

29 |

14 |

14 |

11 |

16.63 ~ 16.78 |

100 ~ 85 |

|

M20 x 2.5 |

R11 |

105 |

30 |

15 |

15 |

12 |

18.63 ~ 18.78 |

100 ~ 85 |

|

美制牙標稱規格 |

精度 |

形狀尺寸 Specification |

2B級下孔徑參考值 Class 2B drill hole dia |

|||||

|

A |

B |

C |

E |

F |

最小-最 |

咬 合 率 % |

||

|

NO.4-40 UNC |

R5 |

46 |

9 |

4 |

6 |

3.2 |

2.53 ~ 2.60 |

100 ~ 70 |

|

NO.5-40 UNC |

R5 |

46 |

9 |

4 |

6 |

3.2 |

2.86 ~ 2.93 |

100 ~ 70 |

|

NO.6-32 UNC |

R5 |

48 |

11 |

4 |

6 |

3.2 |

3.09 ~ 3.17 |

100 ~ 75 |

|

NO.8-32 UNC |

R6 |

52 |

12 |

5 |

7 |

4 |

3.76 ~ 3.84 |

100 ~ 75 |

|

NO.10-24 UNC |

R6 |

60 |

14.5 |

5.5 |

7 |

4.5 |

4.26 ~ 4.35 |

100 ~ 80 |

|

NO.12-24 UNC |

R6 |

60 |

14.5 |

5.5 |

7 |

4.5 |

4.92 ~ 5.01 |

100 ~ 80 |

|

1/4-20 UNC |

R7 |

62 |

17.5 |

6 |

7 |

4.5 |

5.67 ~ 5.78 |

100 ~ 80 |

|

5/16-18 UNC |

R7 |

70 |

22 |

6.1 |

8 |

5 |

7.18 ~ 7.29 |

100 ~ 80 |

|

3/8-16 UNC |

R7 |

75 |

21 |

7 |

8 |

5.5 |

8.66 ~ 8.78 |

100 ~ 80 |

|

7/16-14 UNC |

R7 |

80 |

23 |

8 |

9 |

6 |

10.11 ~ 10.25 |

100 ~ 80 |

|

1/2-13 UNC |

R8 |

85 |

25 |

9 |

10 |

7 |

11.62 ~ 11.78 |

100 ~ 80 |

|

5/8-11 UNC |

R11 |

95 |

27 |

12 |

12 |

9 |

14.62 ~ 14.76 |

100 ~ 85 |

|

3/4-10 UNC |

R12 |

105 |

30 |

14 |

14 |

11 |

17.67 ~ 17.88 |

100 ~ 80 |

1. 使用粉末冶金和特殊高速鋼HSSE以及特殊的螺紋形狀對於廣泛的被削材均可能得到較好的壽命。

2. TIN、TICN表面處理均適合鋼鐵及非鐵金屬,且能做高速切削亦能大幅提升耐久性,得到高速率的攻牙作業。

3. 標準粗牙和標準細牙之形狀尺寸相同。

1. By powder metallurgy and special high-speed steel HSSE and special thread, long tool life processing is possible at wide.

2. TIN, TICN coating, suitable for tapping steel and nonferrous metal alloy, capable of efficient, long life, high speed tapping.

The specification of standard coarse screw thread and standard fine screw thread are the same.